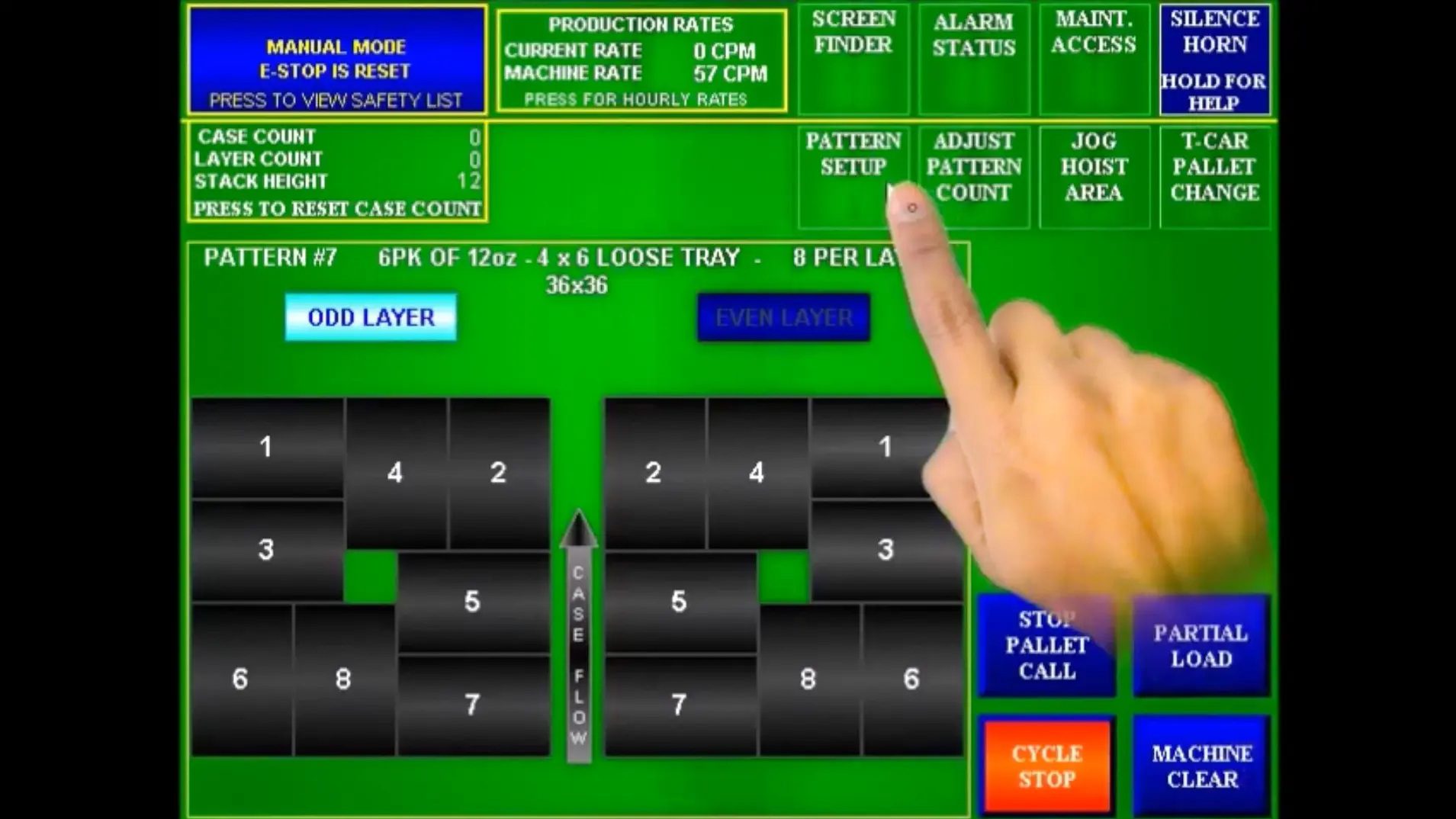

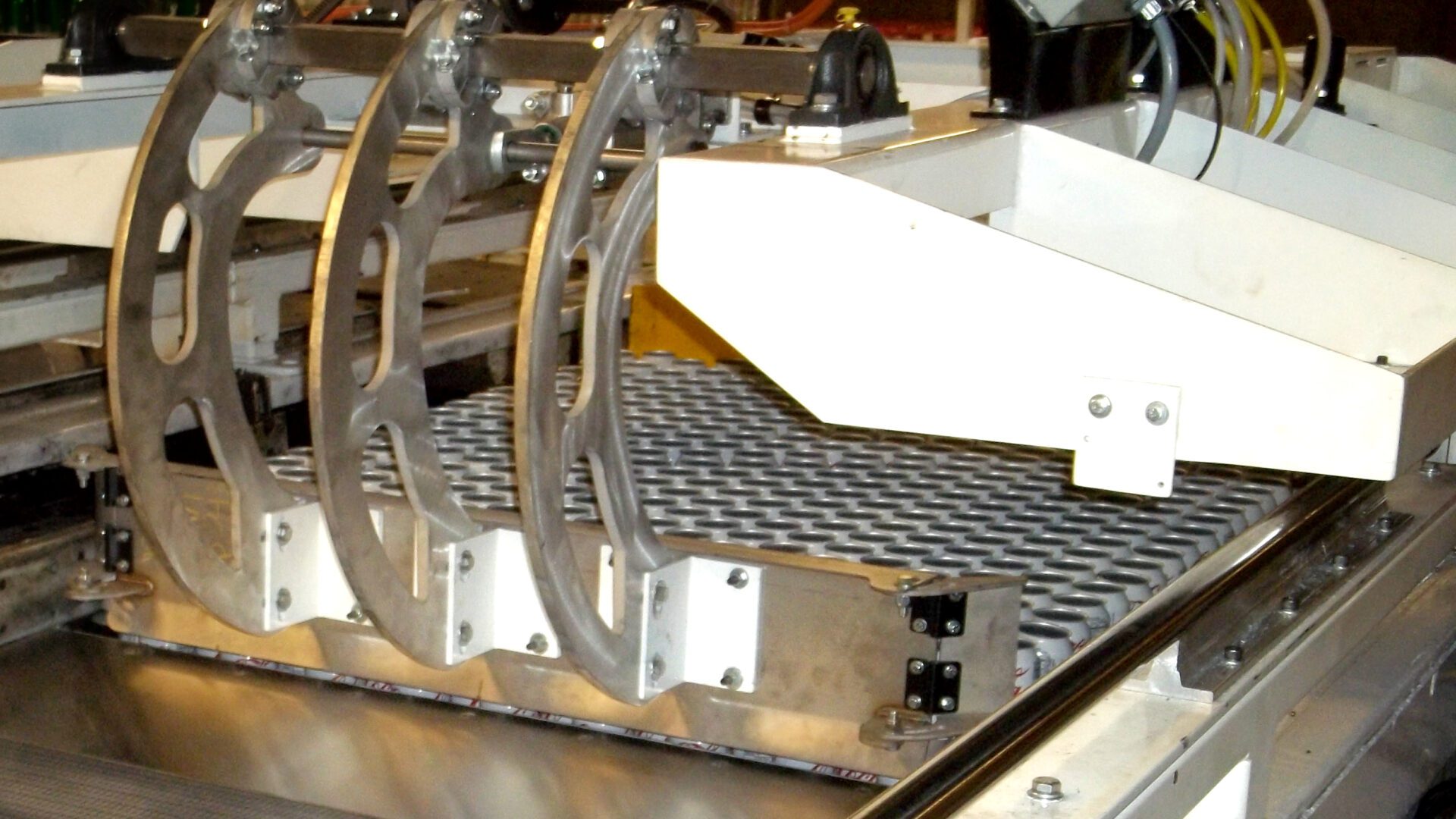

T-TEK's earliest projects included modifications to competitors' palletizers done on the customer's site with minimal downtime. These projects have varied over the years from replacing a processor to stripping a machine down to the frame, repainting, and installing all-new, upgraded components. It may be done to speed up a piece of equipment, upgrade the technology, run a new product, increase safety, or improve the diagnostics. T-TEK has modified equipment originally built by many manufacturers including Alvey, Wyard, Production Automation (PAI), vonGal, Columbia, SECO, and many others.

Field Upgrades are a major part of T-TEK's strategic plan to offer the widest variety of end of line solutions in the industry. Most customers would like new equipment but have a used equipment budget. These field upgrade solutions may fill that need for you. Contact us about any problems that we could help solve with a field upgraded machine.