Depalletizer

Servo controlled Depalletizer

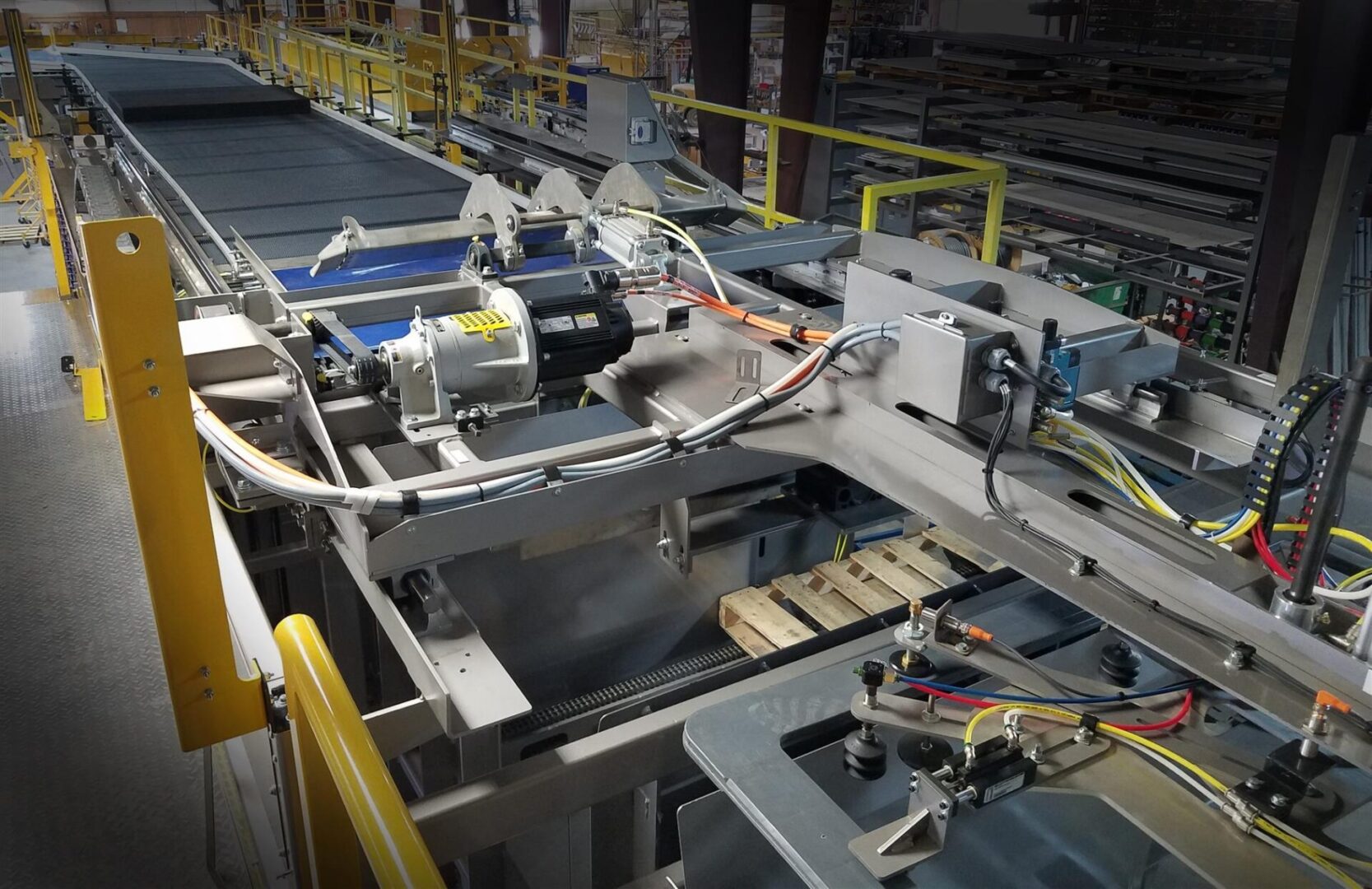

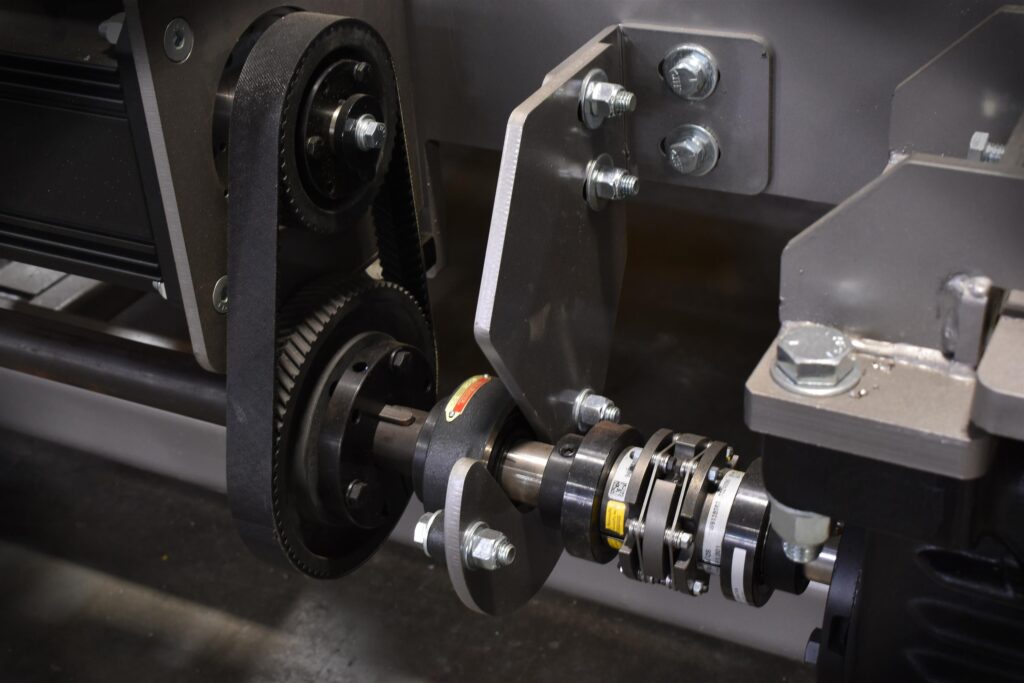

The T-TEK DP Series Servo Depalletizer is a robust, high-speed Depalletizer designed for the rapid deployment of layers. The standard servo hoist uses the same long-lasting drive train as our TS Series palletizer for strength, speed, and low maintenance performance. Depalletizers have been part of the culture of T-TEK since we began in 1996 in the form of modifications and upgrades. Our DP Series was developed to put that experience into practice with features that most Depalletizers do not, cannot match. Our experience with servo drives and regenerative energy in pallet handling has been applied to Depalletizers to create a bottle delivery system for the ages.

T-TEK PACKAGE

Product Features

- Our Depalletizer drives the hoist with a high-speed servo motor that allows rapid pallet change, accurate bottle positioning, with smooth bottle delivery.

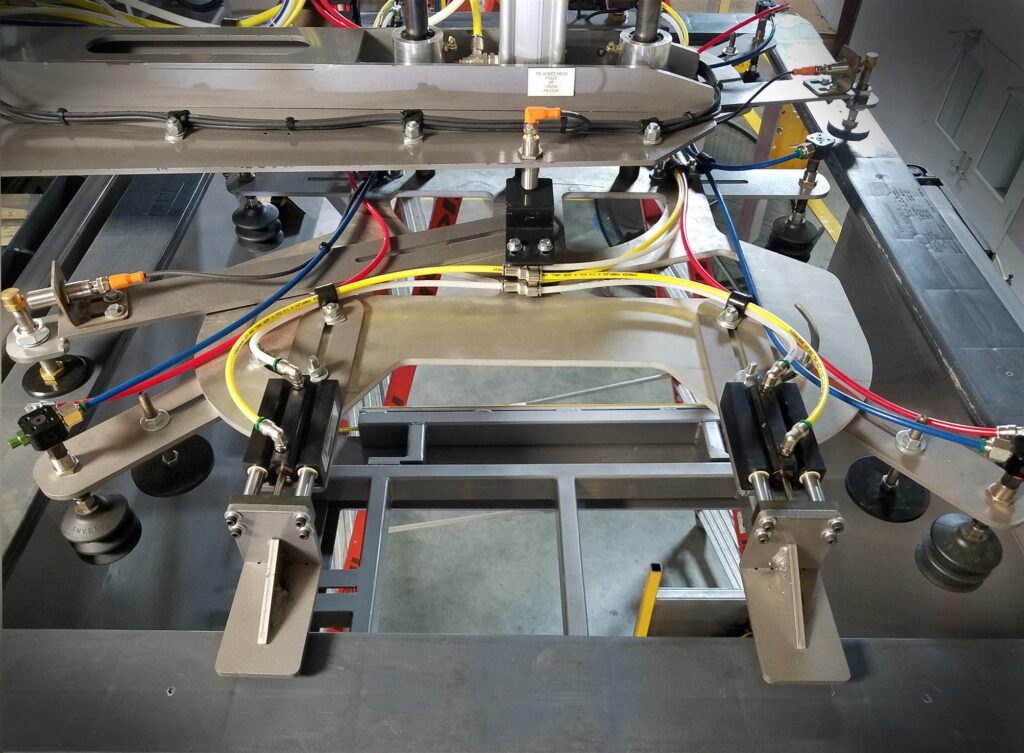

- The sweep head is also servo-driven for high-speed layer handling, accurate head to matt speed matching, and soft product release.

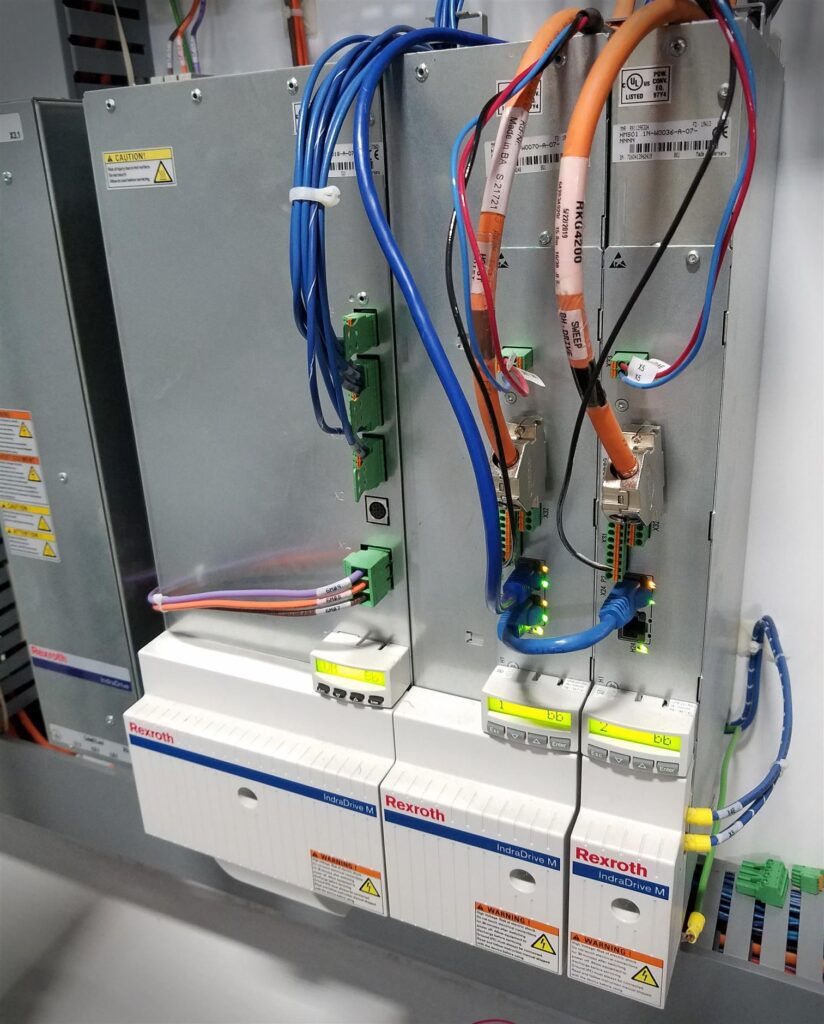

- Regenerative Power Supply returns up to 40% of the energy used by the servos, resulting in an eco-friendly, energy-efficient machine.

- Load squaring side walls and doors retain the product and reduce pinch points where bottles/ cans can hang up.

- Layer position is double-checked versus standard bottle height to position on every sweep using the precision servo encoder.

- All-electric pallet stacker with stacker full detection, warning indication, and full jog functionality.

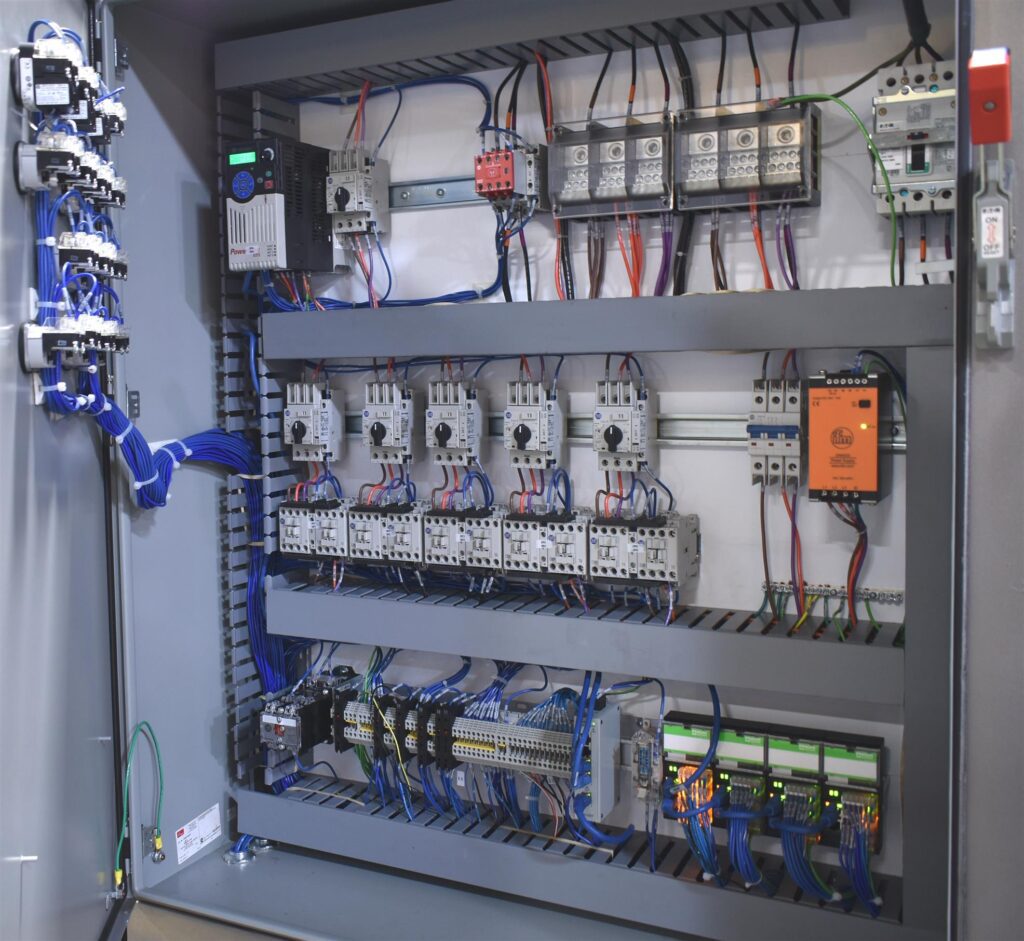

- Light curtains, door sensors, and screens protect the operators while relaying diagnostic information.

- A high-resolution touchscreen with extensive diagnostics simplify troubleshooting and shortens downtime. The screen includes striking visual images, comprehensive jog functionality, and a complete on-screen manual.

- Available options include:

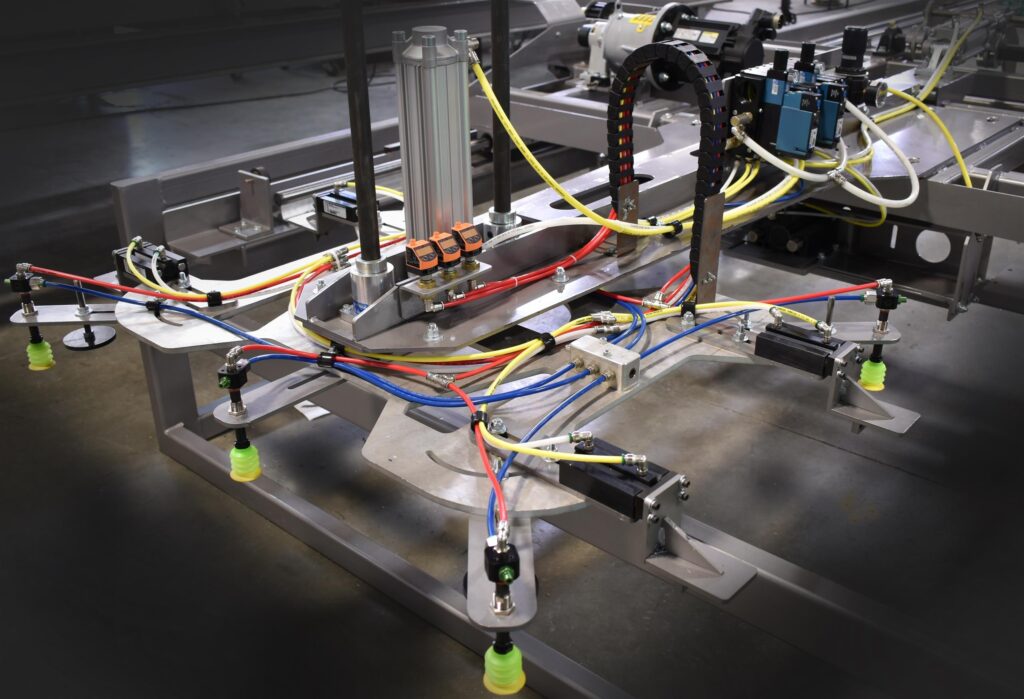

- A separate sheet/ frame head to speed up top frame recovery and separation into unique bins.

- Needle nose Tier sheet grippers

- A servo sweep lift door instead of air for a smoother release of product onto the matt.

- Dunnage Bin for frames

- Dunnage Bin for sheets

- A partial pallet rejects the door to allow half pallets to eject without having to back full loads off of the load conveyor.

- Standard Safety Package

- Trap Key on Remote Operator Panel (ROP)

- E-Stops on Jog Boxes

- Sick safety controller

- Light curtain at Operator access

- Light curtain at Full pallet conveyor hoist entry

ADD-ON ACCESSORIES

Optional Features

- Additional Conveyor(s) at full load infeed area

- Additional Conveyor(s) at empty pallet discharge area

- Additional Operator Touchscreen (HMI) on Main Control Panel

- Additional Platform with Hand Bar Grating

- Stairway(s)

- Safety Addition

- Additional Trap Key for Lockout-Tagout

- Hoist safety lockout pins

- Light curtain on Non – operator side

- Taller handrail opposite the operator touchscreen

- Electrically interlocked gate with fencing

- Empty Pallet outfeed area fencing with Steel mesh access gates

CUSTOM FIT

Equipment Options

- CDLR Load station with Back wall

- 90 Degree Transfer-table on Empty pallet loading area

- 90 Degree Transfer-table on Full Load Pallet Discharge area

- 90 Degree Turn-table on Empty pallet loading area

- 90 Degree Turn-table on Full Load Pallet Discharge area

- Curved Conveyors

- Table-top accumulation conveyor with Three Strand Double Capacity 60 Chains

- Scissor Lift

- T-Car (Transfer Car) System

- Pallet Lifting/Lift Conveyors

- Pallet tipping and flipping equipment

- Test Bench equipment

PHOTO GALLERY

VIDEO GALLERY

We test-run our customer products by executing the Factory Acceptance Test on the assembled machine to verify it is built and operating in accordance with design specifications. Here is a video of testing products on our Depalletizer.

BUILD MY MACHINE

CUSTOM BUILD

Some plants have unique needs. Sometimes an unusual product requires some creative solutions. T-TEK has been building custom equipment to fill those needs since we began. Customers with an odd-shaped space, newly created container, or old equipment that needs to run something new can sometimes benefit from a Custom Solution.

T-TEK enjoys finding ways to fit square pegs in round holes. Every year brings us opportunities to challenge our design team and add to our catalog of custom equipment.

Ready to build your next material handling system? Let’s get started.