TE Series

Efficiency In-Line Palletizer

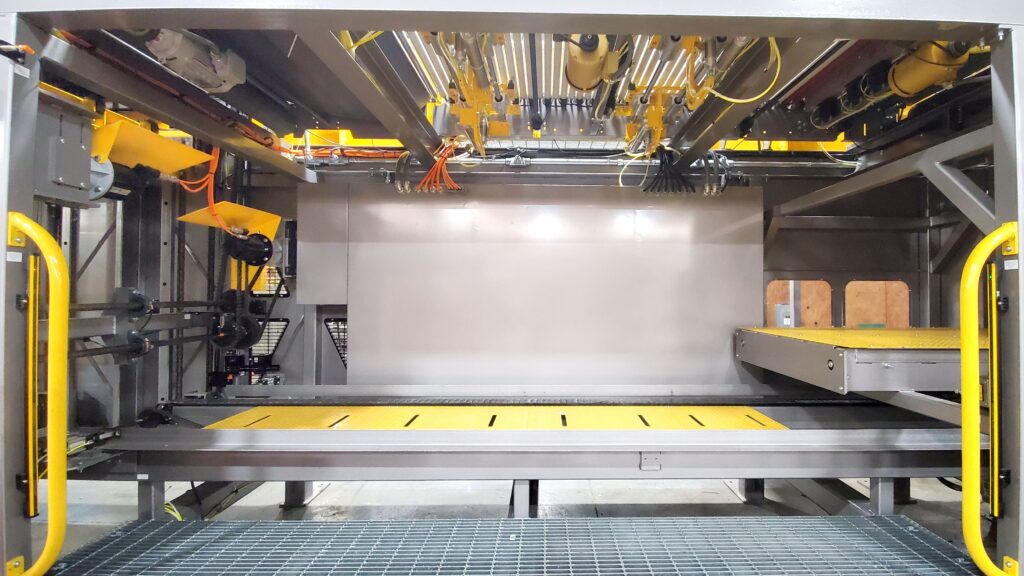

The T-TEK TE Series Palletizer is designed to provide maximum value by including the essential components of the TS Series palletizer, the divider, the heavy-duty hoist, etc. while allowing the customer to choose the options most important to them. These machines run at slightly lower speeds but Speed Packages are an available option. The TE Series palletizer is the newest offering in our line of rugged, in-line palletizers. Customers have demanded an in-line machine at a more economical price. The TE Series bridges the gap between robotic load cells and our TS Series palletizer without compromising our reputation for strength and performance. Contact Us for a closer look at the TE Series and the options available.

- Description

- T-TEK PACKAGE

- ADD-ON ACCESSORIES

- CUSTOM FIT

- PHOTO GALLERY

- VIDEO GALLERY

- BUILD MY MACHINE

Description

Efficiency In-Line Palletizer

The T-TEK TE Series Palletizer is designed to provide maximum value by including the essential components of the TS Series palletizer, the divider, the heavy-duty hoist, etc. while allowing the customer to choose the options most important to them. These machines run at slightly lower speeds but Speed Packages are an available option. The TE Series palletizer is the newest offering in our line of rugged, in-line palletizers. Customers have demanded an in-line machine at a more economical price. The TE Series bridges the gap between robotic load cells and our TS Series palletizer without compromising our reputation for strength and performance. Contact Us for a closer look at the TE Series and the options available.

T-TEK PACKAGE

Product Features

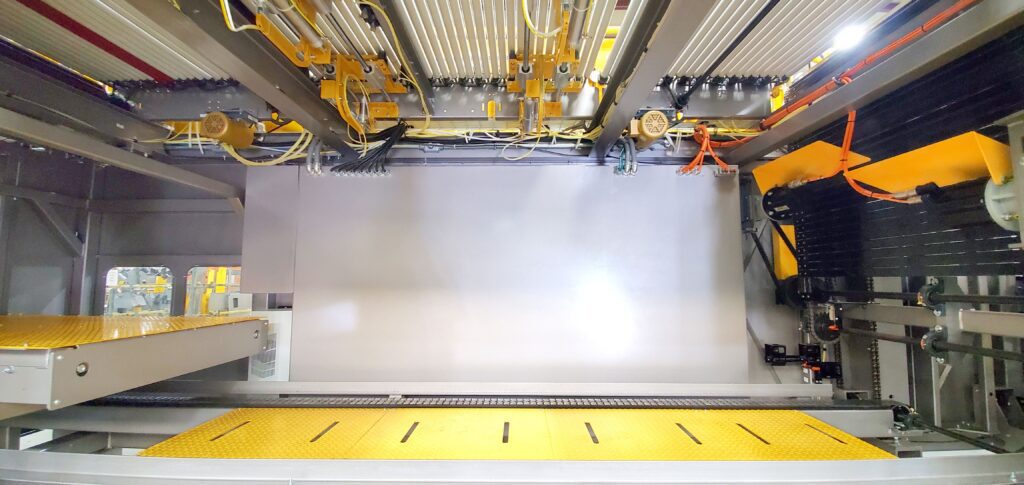

- Servo-driven Hoist for the most gentle handling of full pallets and the shortest layer drop from the apron to pallet in the industry. The hoist drive train is the same proven gearbox, motor combination as our TS Series.

- Lightweight composite Apron slats flex to avoid damage with a low friction surface for consistent control of shrink wrap cases. The Apron is the same as our TS Series Apron.

- Divider case slats use a case hardened pin to follow UHMW covered lanes to minimize wear and maintenance. The Divider is the same as our TS Series Divider.

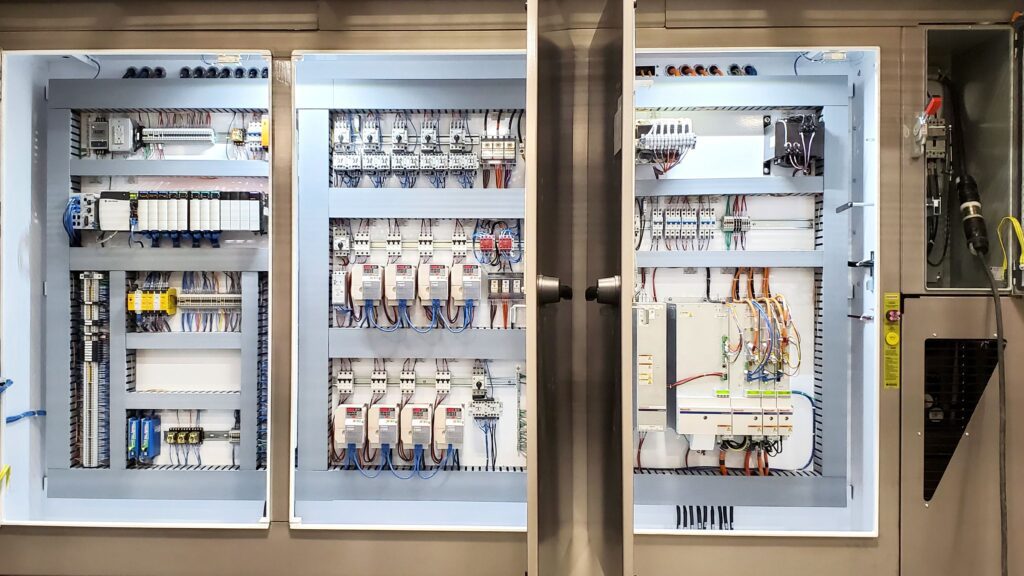

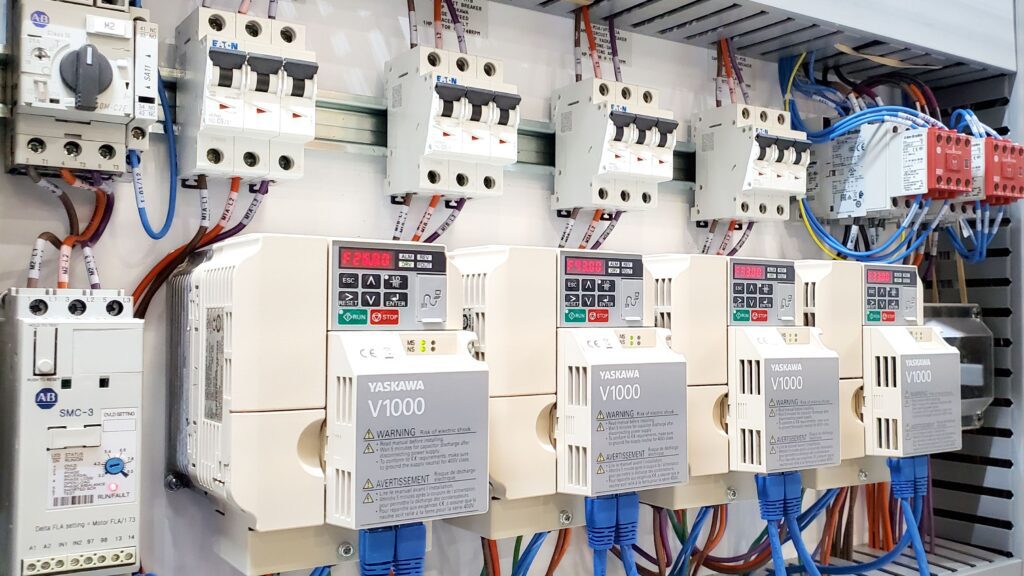

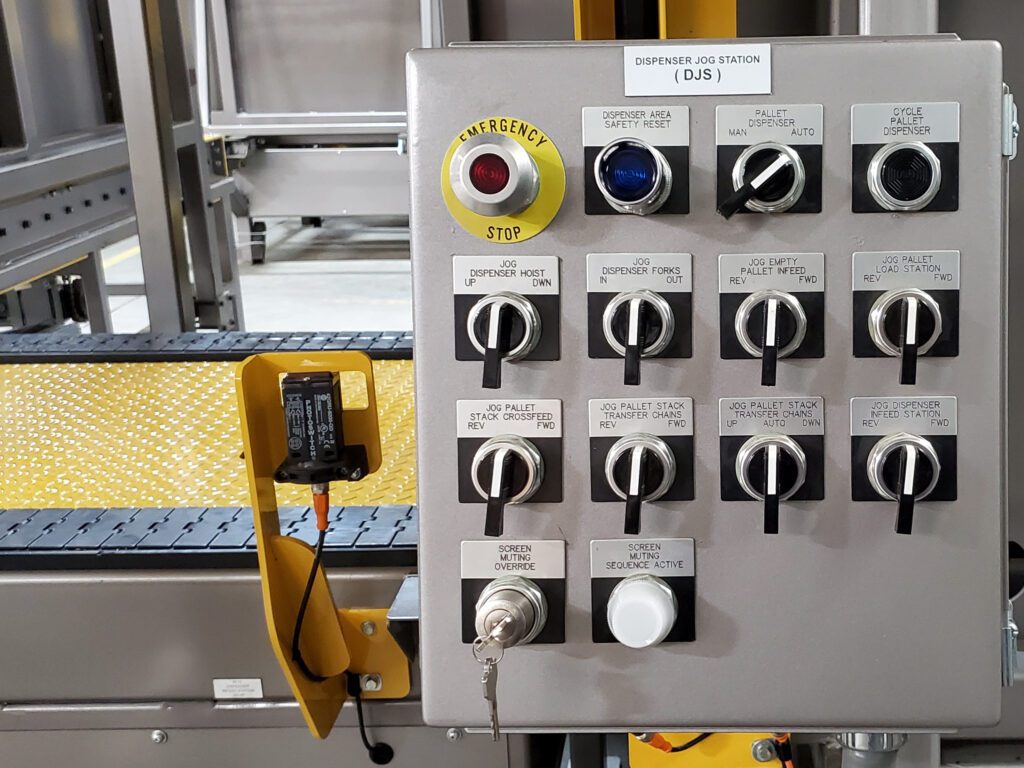

- A high-resolution touchscreen with diagnostics simplify troubleshooting and shortens downtime. The screen includes striking visual images, comprehensive jog functionality, and a complete on-screen manual.

- Light curtains, door sensors, apron covers, and screens protect the operators while relaying diagnostic information.

- The TE Series frame is built as a single frame and is structurally strong.

- A wide variety of case handling components is designed to form even the most complex patterns reliably.

- Options include:

- Speed package: Incorporates the TS Series servo Apron and End Compression and the Regenerative Power Supply which returns up to 40% of the energy used by the servos, resulting in an eco-friendly, energy-efficient machine.

- Diagnostic package: Increase the diagnostic capability of the touchscreen to include most of the same messages and faults of the TS Series.

- Many other options are available.

- Standard Safety Package

- Trap Key on Remote Operator Panel (ROP)

- E-Stops on Jog Boxes

- Sick safety controller

- Light curtain – Accumulator Operator side

- Light curtain – Hoist/Full Load discharge

- Hoist upper access windows

ADD-ON ACCESSORIES

Optional Features

- Sheet Dispenser

- Pattern Forming Area Devices

- Arm Turners (Retractable/Non-retractable)

- Case Stops

- Pin & Slide Turners

- Arc Turners

- Overhead Pushovers @ Row/Layer Stops

- Rakes @ Row/Layer Stops

- Zone Compression

- Auto-adjusting infeed guides

- Auto pallet centering on Pallet Hoist

- Additional Operator Touchscreen (HMI) on Main Control Panel

- Hoist access window on non-operator side

- Additional Platform with Hand Bar Grating

- Additional Stairways

- Safety Addition

- Additional Trap Key for Lockout-Tagout

- Hoist safety lockout pins

- Electrically interlocked Hoist/Apron cover

- Light curtain on Non – operator side

- Taller handrail (42″) opposite the operator touchscreen

- Light curtain in Dispenser Infeed area

- Electrically interlocked gate with fencing

- Empty Pallet Infeed area fencing with Steel mesh access gates

- Case Infeed Tunnel with safely access Gate

- Full Load Outfeed Area Fencing with Steel mesh access gates

CUSTOM FIT

Equipment Options

- CDLR Load station with Back wall

- 90 Degree Transfer-table on Empty pallet loading area

- 90 Degree Transfer-table on Full Load Pallet Discharge area

- 90 Degree Turn-table on Empty pallet loading area

- 90 Degree Turn-table on Full Load Pallet Discharge area

- Curved Conveyors

- Table-top accumulation conveyor with Three Strand Double Capacity 60 Chains

- Tier-sheet Dispenser System

- Scissor Lift

- T-Car (Transfer Car) System

- Pallet Lifting/Lift Conveyors

- Pallet tipping and flipping equipment

- Test Bench equipment

PHOTO GALLERY

VIDEO GALLERY

We test-run our customer products by executing the Factory Acceptance Test on the assembled machine to verify it is built and operating in accordance with design specifications. Here are a few videos of testing products on our TE Series palletizers.

BUILD MY MACHINE

CUSTOM BUILD

Some plants have unique needs. Sometimes an unusual product requires some creative solutions. T-TEK has been building custom equipment to fill those needs since we began. Customers with an odd-shaped space, newly created container, or old equipment that needs to run something new can sometimes benefit from a Custom Solution.

T-TEK enjoys finding ways to fit square pegs in round holes. Every year brings us opportunities to challenge our design team and add to our catalog of custom equipment.

Ready to build your next material handling system? Let’s get started.